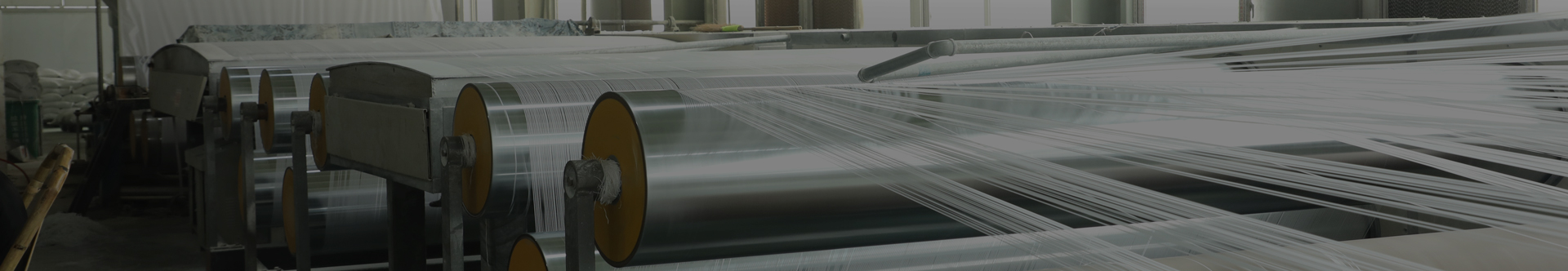

Izikhwama zokupakisha zepulasitiki zenziwe nge-polypropylene (PP) njengento eluhlaza eyinhloko, ekhishwayo, idonswa insimbi, ilukwe kabusha, ilukiwe, futhi yenziwe izikhwama zokupakisha.

I-PP iyipulasitiki ebonisa ngale, i-semi-crystalline thermosetting enokuqina okuphezulu, izakhiwo ezinhle zokuvikela, ukumuncwa kwamanzi aphansi, izinga lokushisa eliphezulu le-ambient, ukuminyana okuphansi kwesihlobo, nezinga lokushisa lengilazi eliphezulu.Iwumthombo oyinhloko wokwenza izikhwama zokupakisha.Izinto zokugcwalisa eziguquliwe ngokuvamile zihlanganisa imicu yengilazi, izinto zokugcwalisa amaminerali, irabha ye-thermoplastic, nokunye okunjalo.

Ububanzi bokusetshenziswa kwezikhwama zokupakisha zepulasitiki bubanzi kakhulu.Kulesi sigaba, ukusetshenziswa okubalulekile kwezikhwama zokupakisha zepulasitiki ukupakishwa kwangaphandle kwemikhiqizo yezolimo, ukupakishwa kwangaphandle kwezikhwama ezilukiwe zepulasitiki, izinto zokupakisha ukudla, ubunjiniyela bendawo, ezokuthutha ezokuvakasha ngamaholide, ukulwa nezikhukhula kanye nezinto eziphuthumayo, njll. Kunezintathu. izinhlobo eziyinhloko zezikhwama zokupakisha: izikhwama zepulasitiki (izikhwama zokupakisha ezingenafilimu), izikhwama zepulasitiki ezihlanganisiwe nezikhwama ezihlukahlukene ezilukiwe.Inqubo yokukhiqiza izikhwama zokupakisha zepulasitiki yilezi: izikhwama ezilukiweyo ziba izikhwama zokupakisha ngemva kokupakishwa nokuphrinta, ukusika nokuthunga nge-laser.

Ngokuya ngomshini nezinto ezisetshenziswayo, ingasikwa nge-laser bese iphrintwa, noma iphrintwe bese isikwa nge-laser.Umshini wokuthunga we-laser othomathikhi ungaqhubeka nenqubo yokupakisha ukuphrinta, ukusika i-laser, umshini wokuthunga, njll., futhi ungenziwa futhi ube amaphakethe we-valve, amaphakethe aphansi, njll. Ukuze uthole izinsimbi eziyisicaba, umthungo ophakathi ungahlanganiswa bese isikhwama singenziwa.Inqubo yokukhiqiza izikhwama zokufaka zepulasitiki eziyinhlanganisela ukusebenzisa izikhwama ezilukiweyo, amatshe ayinhlanganisela noma amafilimu okubuyisana noma ukumbozwa okuyinhlanganisela.Imiqulu etholiwe noma amashidi namaroli angasikwa nge-laser, ahlanganiswe futhi aphrintwe futhi athungwe ngokuhlinzwa ukuze kwenziwe izikhwama ezijwayelekile ezingaphansi komthungo.Bangakwazi futhi ukuvula izimbobo, i-edge crimping, i-laser cutting, ukuphrinta ukupakisha, ukuthunga ngokuhlinzwa kanye nezikhwama zepulasitiki ezilukiwe.Ishidi elitholiwe linganamathiselwa ngomthungo, ukuphrinta kwephakheji, ukusika kwe-laser, i-lid bonding kanye nesikhwama sokunamathisela.Ingakwazi futhi ukushiselwa, ibekwe, igwetshwe, yenziwe amashede okhuni kanye nama-geotextiles angalukiwe.Izindwangu eziyisicaba zingaba ukukhiqizwa nokukhiqiza okuphindaphindiwe noma okungaphindaphindiwe, ama-geotextiles angalukiwe, njll. Indwangu yesigubhu nayo ingakhiqizwa ngokuphindaphindiwe noma cha.

Izinkomba zokusebenza zenqubo yokukhiqiza umshini wokudweba izintambo zepulasitiki zihlukaniswe ikakhulukazi izigaba ezine:

1. Inani lenkomba yokusebenza ngokomzimba.Kunamaphutha amayunithi ngokuyinhloko njengokuphuka kwamandla, amandla okunqamula isihlobo, amandla aqinile, isivinini se-angular, kanye nokuminyana;

2. Amanani ezinkomba zezinto eziguquliwe ngamakhemikhali.Ihlanganisa ikakhulukazi ukuhlanganisa izinto eziguquliwe, ukulungiselela ukuxuba, ukwengeza isilinganiso sezishintshi, kanye nesilinganiso sikamanyolo owenziwe kabusha oyimbudumbudu owenziwe kabusha;

3. Inani lenkomba yokucaciswa kokubekezelela kobukhulu.Ihlanganisa ikakhulukazi ubukhulu bomshini wokudweba izintambo zepulasitiki kanye nobubanzi bocingo oluyisicaba.

4. Izakhiwo zomzimba inani lenkomba ye-rheological.Kukhona ikakhulukazi isilinganiso sokuhlukaniswa kwentambo, isilinganiso sokwehla kwamandla emali, isilinganiso sokusalungiswa kanye nesilinganiso sokuncipha;

Ubuchwepheshe bokucubungula isikhwama se-lined High pressure polyethylene impahla ishiswa yi-extruder, iyancibilika futhi ikhishwe kahle;

Cindezela ipulasitiki emise okwe-barrel ibe yifilimu yepulasitiki emise okomgqomo;ngena ukunciphisa uthuli oluvuthelayo futhi ubangele ama-bubbles tube;

I-splint yokuqondisa izinwele ezimise okwe-herringbone ipholile futhi ibunjwe yindandatho yomoya opholile, futhi i-traction ilethwa ekuguqulweni;

I-roller yesistimu yokushayela idonselwa ku-roller ejikelezayo ngokusebenzisa i-traction belt roller;

Ekugcineni, ukusika kwe-laser kuyenziwa, isikhwama se-lining sikhiqizwa inqubo ye-hot-melt, futhi ekugcineni isithelo sifakwe esikhwameni.

I-polypropylene ehlanzekile ayikwazi ukuhlangabezana nezidingo zemishini yokudweba izintambo zepulasitiki, kodwa futhi idinga ukwengeza iphesenti elithile le-polyethylene, i-calcium bicarbonate kanye ne-masterbatch yombala.Ukwengeza inani elincane le-polyethylene phakathi nayo yonke inqubo ye-extrusion kunganciphisa i-viscosity kanye nezinga lokuncibilika kokugeleza kwezinto ezibonakalayo, kuthuthukise ukugeleza kwamanzi, kuthuthukise i-ductility kanye nokuguquguquka komshini wokudweba ucingo lwepulasitiki kanye nezikhwama zokupakisha zepulasitiki, ukugcina amandla athile aqinile, futhi thuthukisa ukulimala kwe-polypropylene ultra-low lokushisa.

Izithasiselo ze-polypropylene ezithuthukisiwe zinganciphisa izinga lokushisa kanye nengcindezi yokusebenza ezindaweni zokukhiqiza nokucubungula.Thuthukisa ukugeleza kwedatha nokunamathela, uthuthukise amandla okuqina.Ukwengezwa kwe-calcium bicarbonate kungashintsha ukushiyeka kokungafihli okuphelele nokungafihli.Ekwehliseni ukunwebeka, yonke le nqubo iyingozi ekwenziweni kwe-electrostatic njengoba ilimaza ukungqubuzana, ukuthuthukisa ukunamathela kukayinki wokuphrinta wokupakisha nokuphrinta amalogo ophawu lokuthengisa, ukunciphisa ukuqoqwa kwemvelo nokulawula izindleko zemikhiqizo eqediwe ngesikhathi sokulondoloza.

Isikhathi sokuthumela: Jun-29-2022